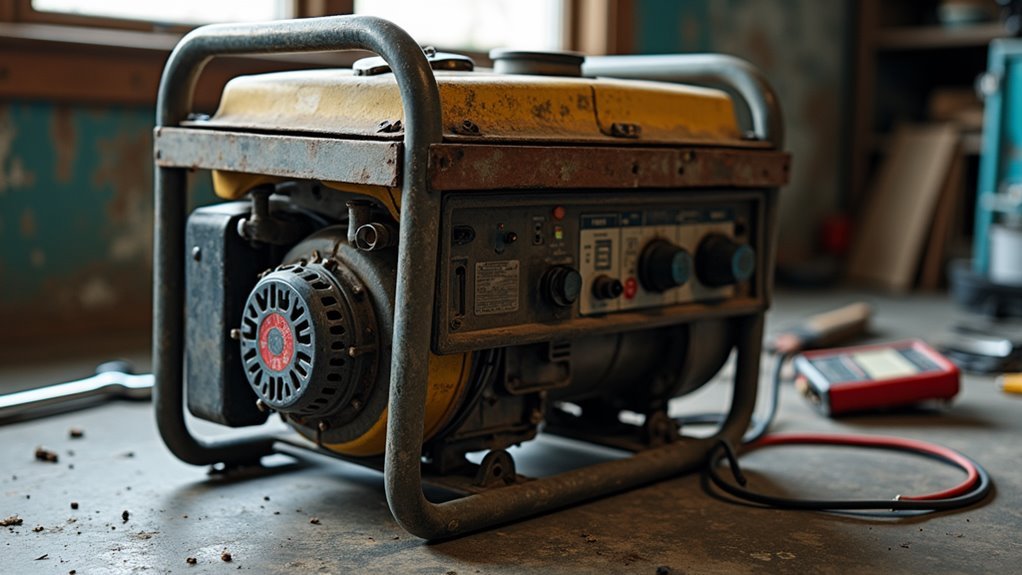

We've all experienced that sinking feeling when a generator fails at the worst possible moment. Whether it's during a power outage or at a critical job site, generator problems can bring operations to a sudden halt. While these issues might seem intimidating at first, most common generator troubles have straightforward solutions that we can tackle with the right knowledge and tools. From mysterious starting problems to concerning noises, let's explore the essential troubleshooting steps that'll help keep your power source running reliably when you need it most.

Generator Won't Start

When your generator fails to start, several common issues could be at fault. Let's walk through the most likely problems so you can get your power back quickly and independently.

First, we'll want to check if you've got fresh fuel in the tank and that the fuel valve is open. Bad or old fuel is one of the most common culprits we see.

Next, we need to examine your battery if you have an electric start model. A weak or dead battery won't provide enough juice to turn the engine over.

We'll also want to make sure the oil level is correct, as many generators have automatic shutoffs when oil runs low. Don't forget to check the spark plug – it might be worn out or fouled up.

If you're in cold weather, your generator might need the choke engaged to start. We recommend trying this even if the temperature seems mild.

Last but not least, check your air filter – a clogged one can prevent proper starting. By working through these steps methodically, you'll often find the issue and get back up and running. Additionally, keeping your generator well-maintained with proper oil maintenance ensures it operates effectively and reliably over time.

Low Power Output

A generator struggling to produce full power can leave you with dimming lights and sluggish appliances. When your generator isn't delivering the juice you need, we'll help you diagnose and fix the issue quickly. Low power output often stems from simple problems we can solve together.

The most common culprits behind weak generator performance include dirty air filters, clogged fuel lines, and worn spark plugs. We've found that regular maintenance prevents most of these issues, but let's tackle the problem step by step to get your power back to full strength.

Here are the key checks we need to perform:

- Test the voltage output with a multimeter at different load levels to pinpoint where the power drop occurs.

- Inspect the automatic voltage regulator (AVR) for signs of damage or loose connections.

- Check the engine's RPM – it should maintain steady speed under load.

If these initial checks don't solve the problem, we'll want to look at the carburetor for fuel delivery issues or examine the brushes and windings for wear. Regular maintenance is crucial as it includes tasks such as changing oil and filter, which can directly impact the generator's performance.

Surging or Fluctuating Power

Just as frustrating as low power output is the erratic behavior of a surging generator. When our generator's power fluctuates up and down, it's not just annoying – it can damage our sensitive electronics and appliances. We're here to help you tackle this common problem head-on.

Most surging issues stem from three main culprits: fuel delivery problems, dirty carburetor components, or a faulty automatic voltage regulator (AVR).

Let's check the fuel system first – a clogged fuel filter or deteriorating fuel lines can cause irregular fuel flow. If that's not it, we'll need to inspect and clean the carburetor, as built-up debris often disrupts proper fuel-air mixture.

When fuel isn't the issue, we'll turn our attention to the AVR, which controls our generator's electrical output. A failing AVR can't maintain steady voltage, causing those frustrating power swings.

We can test this by measuring voltage output with a multimeter – if readings bounce around considerably, we've likely found our problem.

Sometimes, simply adjusting the governor spring tension can smooth out minor surging issues, but more severe cases might require component replacement.

Excessive Fuel Consumption

High fuel consumption in your generator isn't just costly – it's often a warning sign of underlying mechanical issues. When your generator starts guzzling more fuel than usual, it's telling you something's not quite right.

We'll help you identify what's causing this problem and how to fix it before it leads to bigger headaches down the road.

Let's look at the most common reasons your generator might be burning through fuel too quickly:

- Dirty or clogged air filters that make your generator work harder than necessary, forcing it to use more fuel to maintain power output.

- Faulty fuel injectors or carburetor issues that prevent proper fuel atomization, leading to incomplete combustion and wasted fuel.

- Incorrect generator sizing where you're using a unit that's too powerful for your actual needs, resulting in unnecessary fuel consumption.

We recommend checking these issues first before calling in a professional.

Often, simple maintenance like cleaning filters or adjusting the carburetor can dramatically improve fuel efficiency.

Unusual Noises During Operation

Strange noises coming from your generator often signal mechanical problems that need immediate attention. When we hear knocking, grinding, or rattling sounds, it's essential to identify and address the issue before it leads to major damage or complete failure.

Let's look at common noise issues and what they mean. A steady knocking sound typically indicates loose or worn connecting rods, while high-pitched whining might point to bearing problems.

We'll often hear a metallic rattling when components like the flywheel or fan blade become loose. If there's a loud banging noise, it could mean your generator's pistons are misfiring or the timing is off.

Don't ignore these warning signs – they're your generator's way of telling you something's wrong. We recommend shutting down the unit immediately if you hear any unusual sounds.

It's better to have a professional check it out than risk catastrophic engine failure. While some noises might seem minor, they can quickly escalate into costly repairs if left unchecked.

Regular maintenance and prompt attention to unusual sounds will help keep your generator running smoothly and reliably when you need it most.

Oil Leaks and Maintenance

While unusual noises may be the first sign of generator problems, oil leaks represent another common issue that demands immediate attention.

We've found that oil leaks often start small but can quickly develop into major headaches if left unchecked. When you spot those telltale dark spots under your generator, it's time to take action before the situation gets worse.

Let's focus on the three main causes of oil leaks we typically encounter:

- Worn-out gaskets and seals that have degraded over time, especially around the oil pan and valve cover areas.

- Loose drain plugs or filter connections that weren't properly tightened during the last oil change.

- Cracks in the engine block or oil pan, usually caused by impact damage or severe overheating.

Regular maintenance is your best defense against oil leaks.

We recommend checking oil levels weekly and inspecting for leaks during each use. Don't wait until you're facing an emergency – keeping up with basic maintenance now means you'll have reliable power when you need it most.

If you spot a leak, it's best to address it immediately rather than risk damaging your generator's engine.

Electrical Connection Problems

Electrical connection issues represent four common generator problems that can disrupt your power supply.

First, we often see loose or corroded battery connections that prevent proper starting. Let's fix this by cleaning the terminals with a wire brush and ensuring they're tight.

Second, faulty circuit breakers can trip repeatedly – we'll want to inspect and replace any that show signs of wear.

Third, we frequently encounter worn or damaged power cords that need immediate replacement to prevent shorts and safety hazards.

The fourth issue we'll tackle involves outlet problems. When outlets aren't delivering power, we'll check the GFCI reset buttons and verify all connections are secure.

Don't forget to test your generator's voltage output using a multimeter – it should match your unit's specifications. If you're getting inconsistent readings, we recommend inspecting all wiring connections from the alternator to the control panel.

Battery Charging Issues

Building on our electrical troubleshooting, let's address why your generator's battery won't hold a charge. A failing battery can leave you powerless when you need backup energy the most, but we'll help you identify and fix these issues before they become major problems.

Your generator's battery system isn't just about storing power – it's about maintaining your independence and readiness.

The most common battery charging problems can be traced to three main causes:

- Corroded or loose battery terminals that prevent proper charging flow – you'll notice white or greenish buildup around the connections that needs cleaning with a wire brush.

- A failing voltage regulator that's not converting power correctly – you'll typically see inconsistent charging patterns or battery drain even when the generator's running.

- Deteriorated battery cells that can no longer hold a charge – if your battery's more than three years old, it might be time for a replacement.

We recommend checking these components in order, starting with the simplest fix.

Clean connections often solve the problem, but don't hesitate to test the voltage regulator or replace an aging battery if needed.

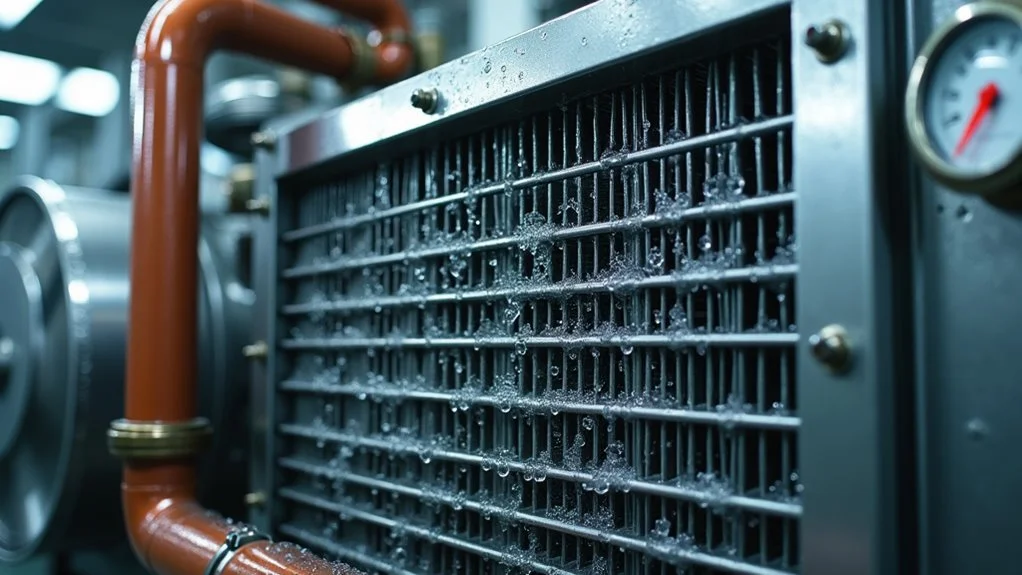

Overheating and Cooling System

A generator's cooling system plays a vital role in preventing dangerous overheating that can damage or destroy your equipment. When we're troubleshooting overheating issues, we'll first check for proper airflow around the unit.

Make sure there's at least three feet of clearance on all sides of your generator to allow adequate ventilation.

Next, we'll inspect the cooling fins and radiator for dirt, debris, or blockages that could restrict airflow. It's important to keep these areas clean – we recommend using compressed air or a soft brush to remove buildup regularly.

Don't forget to check the coolant levels and look for any leaks in the system.

If your generator continues to overheat, we'll want to examine the thermostat and cooling fan operation. A malfunctioning thermostat won't properly regulate temperature, while a failing fan won't provide enough airflow.

You'll also want to verify that your generator isn't being overworked – running too many high-draw appliances simultaneously can cause excessive heat buildup.

Fuel System Blockages

Many fuel system blockages stem from contaminated or degraded fuel sitting in the tank for extended periods.

We'll often see this problem when generators haven't been used for months, especially if the fuel wasn't properly treated before storage. When dirt, rust, or water gets into your fuel system, it can clog essential components and prevent your generator from running smoothly.

Let's look at the key signs that you're dealing with a fuel system blockage:

- Your generator sputters or runs roughly, especially when you increase the load

- The engine frequently stalls or won't start at all, even with a full tank

- You notice unusual smoke coming from the exhaust, often dark or excessive

We can prevent most fuel system blockages by maintaining clean fuel and proper filtration.

It's important to use fresh fuel, replace fuel filters regularly, and add a quality fuel stabilizer when storing your generator. If you've already got a blockage, don't worry – we can usually fix it by draining the old fuel, cleaning the fuel lines, and replacing the filters.

Frequently Asked Questions

How Long Can I Store Fuel Before It Needs to Be Replaced?

We recommend using fuel within 3-6 months for best performance. If you've got stabilizer added, you can extend storage up to 12 months before it starts degrading your generator's performance.

Can I Run My Generator in the Rain or Snow?

Like a delicate smartphone, we don't want our generators exposed to rain or snow. We'll need a well-ventilated canopy or shelter to protect it while running in wet conditions.

What Size Generator Do I Need for My Specific Power Requirements?

We'll help you calculate your needs by adding up your essential appliances' wattages. Let's start with your vital items, then factor in surge watts for starting power requirements.

Is It Safe to Parallel Connect Two Different Generator Models?

We don't recommend connecting different generator models in parallel. It's risky since they'll likely have mismatched voltage, frequency, and phase characteristics that can damage your equipment and create safety hazards.

How Often Should I Exercise My Standby Generator When Not in Use?

We recommend exercising your standby generator every week for 20-30 minutes under load. It'll keep fluids circulating, prevent fuel system issues, and guarantee your generator's ready when you need it.

Conclusion

Like a well-tuned engine, we've explored the essential steps to keep our generators running smoothly. We've learned that addressing common problems early – from starting issues to cooling system maintenance – helps prevent bigger headaches down the road. Let's remember that regular checkups and prompt attention to unusual signs are our best tools in maintaining these power-providing workhorses. With these solutions in hand, we're ready to tackle any generator challenge.