Let's explore how a well-maintained fuel system keeps our generators running at peak performance. We've seen countless generator failures that could have been prevented with proper fuel system care, and we're going to share the essential maintenance steps that make all the difference. From selecting the right fuel to establishing a solid maintenance schedule, these proven practices will help protect your investment and guarantee reliable power when you need it most. Whether you're a seasoned operator or new to generator ownership, there's always more to learn about keeping your machine's lifeblood flowing smoothly.

Understanding Your Generator's Fuel System

In order to properly maintain your generator's fuel system, you'll need to understand its core components and how they work together.

Let's break down the key parts: the fuel tank, fuel lines, filters, and carburetor or fuel injectors. These parts work as a team to keep your generator running smoothly.

The fuel tank stores your generator's fuel supply and includes a tank cap that lets air flow while keeping debris out.

From there, fuel lines carry the gas or diesel to where it needs to go, kind of like the veins in your body.

Along the way, fuel filters catch dirt and rust that could harm your generator – they're basically security guards protecting your engine. Regular maintenance tasks are vital to ensure the longevity of these components.

Common Fuel System Problems

Even well-maintained fuel systems can develop problems over time.

When we're relying on our generators for backup power, these issues can leave us vulnerable during emergencies.

Let's look at the most common fuel system problems we'll likely encounter and how to spot them early.

Contaminated fuel is often the biggest culprit behind fuel system failures.

Water, dirt, and debris can sneak into our fuel tanks through loose caps or during refueling, causing serious performance issues.

We'll notice sputtering, rough running, or complete failure if we don't address these contaminants quickly.

Here are the three most frequent fuel system problems we need to watch for:

- Fuel degradation: Old fuel breaks down after 6-12 months, forming sticky deposits that clog filters and injectors.

- Microbial growth: Bacteria and fungi thrive in fuel tanks, especially when water is present, creating sludge that blocks fuel flow.

- Clogged filters: Accumulated debris and deteriorated fuel components restrict fuel flow, starving the engine of needed fuel.

Regular inspection and maintenance help us catch these issues before they become major problems. Additionally, understanding proper fueling practices is essential for keeping our fuel systems in good condition.

Selecting Quality Fuel

Selecting proper fuel can make or break our generator's performance and longevity. We'll want to guarantee we're using the right grade and quality of fuel to keep our power flowing when we need it most. Let's look at the key factors that'll help us make smart fuel choices for our generators.

| Fuel Type | Best For | Key Benefits |

|---|---|---|

| Regular Gas (87) | Small Portable Units | Affordable & Readily Available |

| Premium Gas (91+) | High-Performance Models | Better Engine Protection |

| Ultra-Low Sulfur Diesel | Large Standby Units | Longer Storage Life |

We're going to want to avoid fuel that's been sitting around for months, as it can break down and cause problems. Fresh fuel from reputable stations is our best bet, and we should always check our generator's manual for specific requirements. When we're storing fuel for emergency backup, we'll need to add a quality fuel stabilizer to keep it fresh. Remember, we're not just protecting our investment – we're guaranteeing our independence when the power goes out. Clean, fresh fuel helps us maintain that freedom to keep our lives running smoothly, no matter what comes our way.

Fuel Storage Best Practices

Proper fuel storage stands as a critical factor in maintaining generator reliability. We've found that following smart storage practices helps prevent costly repairs and guarantees our generators start when we need them most.

Let's look at the essential steps that'll keep our fuel in top condition and ready for action.

We need to focus on three key elements of fuel storage that make all the difference:

- Store fuel in clean, sealed containers designed specifically for your fuel type, and keep them in a cool, dry place away from direct sunlight to prevent degradation and contamination.

- Don't fill containers completely – leave about 10% space for fuel expansion during temperature changes, which helps prevent pressure buildup and container damage.

- Rotate stored fuel every 6 months by using it in your vehicles and replacing it with fresh fuel, since old fuel can break down and cause engine problems.

We'll also want to check our stored fuel regularly for signs of contamination like water, rust, or debris.

If we notice any changes in color or smell, it's time to dispose of the fuel properly and start fresh.

Cleaning The Fuel Tank

Inside every generator's fuel tank, sediment and contaminants naturally build up over time, making regular cleaning vital for peak performance. We'll want to tackle this maintenance task at least once a year to keep our generators running smoothly and reliably.

Let's start by draining the old fuel into approved containers. We'll remove the fuel tank from the generator and use a flashlight to inspect the interior for rust, debris, or sludge buildup.

With a clean cloth or sponge, we can wipe down the tank's interior walls, being careful not to leave any fabric remnants behind. For stubborn deposits, we'll use a specialized fuel tank cleaning solution that won't damage the tank's surfaces.

After cleaning, it's imperative that we thoroughly dry the tank's interior to prevent water contamination in our fresh fuel. We can use compressed air or let it air dry completely.

Before reinstalling the tank, we'll check and clean the fuel lines and replace the fuel filter. Once everything's back together, we'll add fresh fuel and run the generator briefly to verify proper operation and check for any leaks.

Maintaining Fuel Lines

Well-maintained fuel lines carry clean fuel from the tank to the engine, preventing costly repairs and unexpected shutdowns.

We can't stress enough how essential these important pathways are for keeping your generator running when you need it most. Let's make sure your fuel lines stay in prime condition with proper maintenance.

To maintain your generator's fuel lines effectively, we recommend following these essential steps:

- Inspect your fuel lines monthly for signs of wear, cracks, or loose connections – don't wait for problems to develop before taking action. If you spot any issues, replace the lines immediately.

- Clean the fuel line filters every three months using appropriate solvents and compressed air to remove buildup that can restrict fuel flow. Remember to wear protective gear during this process.

- Check all connection points where fuel lines meet the tank and engine, ensuring clamps are tight and seals aren't deteriorating. A loose connection can lead to dangerous fuel leaks.

We know you value self-reliance, and that's why it's important to keep these maintenance tasks on your regular schedule.

With proper attention to your fuel lines, you'll have a generator that's ready whenever you need it.

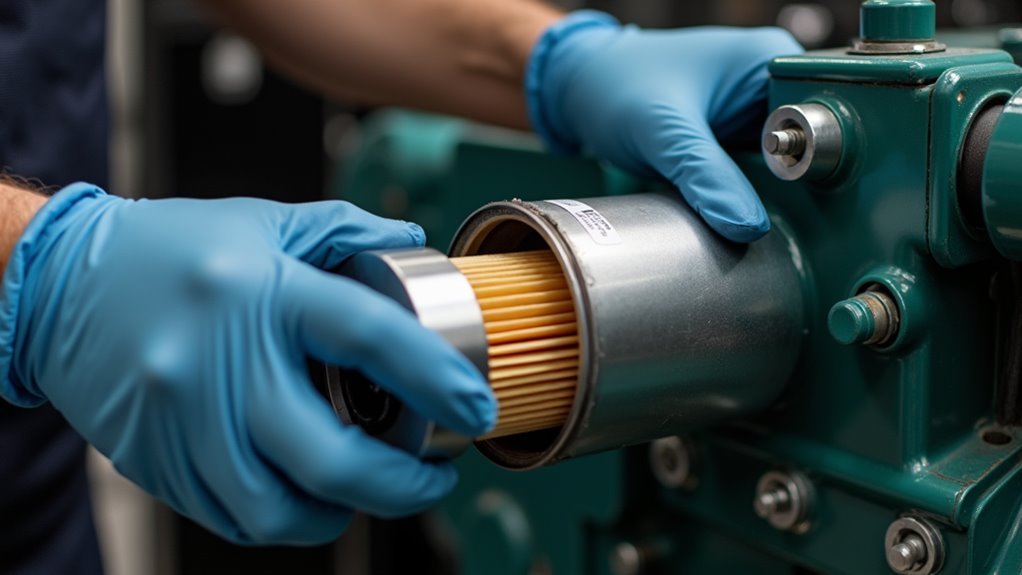

Filter Replacement Schedule

A consistent filter replacement schedule serves as your first line of defense against fuel system contamination.

We recommend changing your generator's fuel filter every 200 operating hours or at least once per year, whichever comes first.

Let's not wait until we notice performance issues – being proactive keeps our generators running reliably when we need them most.

Start by marking your calendar with regular filter check dates.

We can easily inspect the filter's condition by looking for discoloration or debris buildup through the translucent housing.

If we notice the filter appearing darker than usual or spot visible particles, it's time for a replacement, even if we haven't hit our scheduled change date.

For those of us living in dustier areas or using our generators frequently, we'll want to check filters more often – maybe every 100 hours.

It's better to change filters too early than too late.

Remember, a clean filter not only protects our generator's engine but also helps maintain peak fuel efficiency and power output.

When we stick to our maintenance schedule, we're ensuring our generator's ready to power through any situation.

Testing Fuel System Components

Regular testing of fuel system components helps us catch potential issues before they lead to generator failure.

We'll want to check these parts every three months to guarantee everything's working properly and our generator stays ready for action. By staying on top of testing, we're protecting our investment and maintaining our energy independence.

Let's focus on three essential tests we need to perform:

- Check the fuel pressure using a gauge at the carburetor or fuel pump – proper readings should match your owner's manual specifications.

- Test fuel lines and connections for leaks by inspecting fittings and hoses while the system's pressurized.

- Verify proper fuel pump operation by listening for normal humming sounds and measuring output pressure.

When we're testing these components, we'll want to keep detailed records of our readings and observations. This helps us track changes over time and spot developing problems.

If you're not comfortable performing these tests yourself, don't hesitate to call a professional – it's better to be safe than risk damaging expensive components or compromising your generator's reliability.

Emergency Fuel System Troubleshooting

Despite thorough testing and maintenance, fuel system problems can still arise unexpectedly. When you're faced with a fuel system emergency, staying calm and working through basic troubleshooting steps can help get your generator running again quickly.

First, let's check the basics – make sure there's fuel in the tank and the fuel shutoff valve is open. If those check out, we'll want to listen for the fuel pump running when you try to start the generator. No sound could mean a failed pump or blown fuse.

Next, we'll inspect the fuel lines for any visible kinks, cracks, or leaks. Sometimes, the simplest problems are the culprits.

If basic checks don't solve the issue, we'll need to look at the fuel filter. A clogged filter can starve your generator of fuel, but it's usually quick to replace.

Don't forget to check for water contamination in the fuel – a common problem that's often overlooked. You can drain a small sample from the tank's bottom to check for separation.

If you're still stuck, it's time to inspect the carburetor or fuel injectors, depending on your model.

Frequently Asked Questions

Can I Use Automotive Fuel Additives in My Generator?

We don't recommend using automotive additives in your generator as they're not designed for small engines. Stick with additives specifically made for small engines to protect your fuel system.

What's the Maximum Altitude My Generator Can Operate At?

We've seen generators work from sea level to the moon! But realistically, most portable generators can run up to 7,000 feet before they'll need retuning – let's keep that freedom-loving power flowing.

How Does Extreme Cold Affect My Generator's Fuel Consumption Rate?

We'll see your generator use more fuel in extreme cold since it's working harder to start and run. You'll need to plan for 10-15% higher consumption when temperatures drop below freezing.

Should I Warm up My Generator Before Connecting Heavy Loads?

We'd strongly recommend giving your power companion a 2-3 minute warmup before releasing those big loads. It's like stretching before a workout – letting the engine reach peak performance first.

Can I Switch Between Different Fuel Types While My Generator Is Running?

We don't recommend switching fuels while your generator's running – it's dangerous and could damage your machine. Always shut down completely before changing fuel types to protect your investment.

Conclusion

We've covered the nuts and bolts of keeping your generator's fuel system running like a well-oiled machine. By following these maintenance steps, we're protecting our investment and ensuring reliable power when we need it most. Let's not wait until problems surface – regular cleaning, inspections, and filter changes are our best defense. Together, we'll keep our generators humming along and ready for action whenever storms come knocking.